Is the Technology behind the Hydrofoil Usable?

Alinghi Red Bull Racing BoatOne racing Orient Express Racing Team on day 1 of racing at the Louis Vuitton Cup in Barcelona, Spain. 29 August 2024 // Samo Vidic / Alinghi Red Bull Racing // SI202408290401 // Usage for editorial use only //

The principle that allows America’s Cup sailing boats to rise out of the water and skim the surface is called foiling. These boats, known as AC75s, use hydrofoils, which are wing-like structures mounted under the hull. When the boat reaches a certain speed, the hydrofoils generate enough lift to raise the hull out of the water, significantly reducing drag and allowing the boat to achieve much higher speeds.

This technology has revolutionized competitive sailing, enabling boats to reach speeds that were previously unimaginable. The AC75s can even achieve speeds of over 50 knots (about 93 km/h) under the right conditions.

The weight versus speed ratio needed to lift a vessel out of the water and sail on its hydrofoils depends on several factors, including the design of the hydrofoils, the weight of the vessel, and the water conditions. However, the general principle is that the lift generated by the hydrofoils must equal or exceed the weight of the vessel.

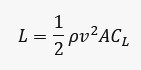

The lift force ( L ) generated by a hydrofoil can be described by the equation:

where:

- ( \rho ) is the density of the water,

- ( v ) is the speed of the vessel through the water,

- ( A ) is the area of the hydrofoil,

- ( C_L ) is the lift coefficient, which depends on the shape of the hydrofoil and the angle of attack.

To achieve foiling, the speed ( v ) must be high enough so that the lift ( L ) equals the weight ( W ) of the vessel:

where:

- ( m ) is the mass of the vessel,

- ( g ) is the acceleration due to gravity.

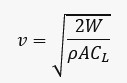

By rearranging the lift equation, you can solve for the required speed ( v ):

This equation shows that for a given weight, increasing the speed, the area of the hydrofoil, or the lift coefficient will help achieve the necessary lift to foil.

Optimizing hydrofoil design involves several key factors to enhance performance, stability, and efficiency. Here are some important aspects:

1. Foil Shape and Aspect Ratio

- Low Aspect Ratio Foils: These have a shorter wingspan and a wider chord, providing more lift at lower speeds, which is ideal for beginners or for stability in rough conditions.

- High Aspect Ratio Foils: These have a longer wingspan and a narrower chord, offering higher speeds and better efficiency but requiring more skill to control.

2. Material Selection

- Carbon Fiber: Commonly used for its high strength-to-weight ratio and stiffness, which helps in reducing drag and increasing speed.

- G-10 Fiberglass: An alternative material that offers good performance at a lower cost.

3. Hydrofoil Components

- Foil Head: Connects the hydrofoil to the board or hull.

- Foil Mast: The vertical component that determines the height at which the vessel rides above the water.

- Fuselage: Connects the front and rear wings, affecting the stability and maneuverability.

- Front Wing: The primary lift-generating component.

- Stabilizer (Rear Wing): Provides stability and control1.

4. Hydrodynamic Efficiency

- Lift-to-Drag Ratio: Optimizing this ratio is crucial for performance. A higher lift-to-drag ratio means more efficient lift generation with less drag, allowing for higher speeds and better fuel efficiency.

- Cavitation and Ventilation: Minimizing these phenomena is essential. Cavitation occurs when low pressure causes water to vaporize, creating bubbles that can damage the foil. Ventilation happens when air is drawn down along the foil, reducing lift3.

5. Modularity and Customization

- Many modern hydrofoil systems are modular, allowing users to mix and match components to suit their specific needs and preferences. This flexibility helps in fine-tuning the performance based on different conditions and riding styles.

6. Advanced Techniques

- Modal Analysis: Used to optimize the dynamic behavior of hydrofoils by tuning the system to specific natural frequencies, enhancing stability and performance4.

By carefully considering these factors, designers can create hydrofoils that offer superior performance, stability, and efficiency, making them suitable for a wide range of applications from recreational boarding to high-speed maritime vessels.

On vessels powered by electric motors, is the range extended in comparison to the range when not using hydrofoils

Using hydrofoils on vessels powered by electric motors can extend the range compared to when not using hydrofoils. This is primarily due to the significant reduction in drag when the vessel is lifted out of the water. Here’s how it works:

Reduced Drag

When a vessel is lifted onto its hydrofoils, the hull is no longer in contact with the water, which drastically reduces hydrodynamic drag. This means the electric motor doesn’t have to work as hard to maintain speed, leading to more efficient energy use and extended range.

Increased Efficiency

With less drag, the vessel can achieve higher speeds with the same amount of power. This efficiency translates to longer distances traveled on a single charge of the battery.

Energy Savings

The energy savings from reduced drag can be substantial. For electric-powered vessels, this means the battery can last longer, allowing for extended trips without needing to recharge as frequently.

Real-World Examples

Several electric hydrofoil boats, like the Candela C-8, have demonstrated this principle effectively. These boats can travel longer distances on a single charge compared to traditional electric boats without hydrofoils.

Considerations

- Weight and Balance: Proper weight distribution and balance are crucial for optimal hydrofoil performance.

- Speed Threshold: The vessel needs to reach a certain speed to lift onto the hydrofoils, which might require more initial power.

Overall, hydrofoils can significantly enhance the range and efficiency of electric-powered vessels, making them a popular choice for modern, eco-friendly boating.